- 您现在的位置:买卖IC网 > Sheet目录865 > JWK316BJ106KD-T (Taiyo Yuden)CAP CER 10UF 6.3V 10% X5R 0612

�� �

�

�

�◆Soldering�

�?� Ceramic� chip� capacitors� are� susceptible� to� thermal� shock� when� exposed� to� rapid� or� concentrated� heating� or� rapid� cooling.�

�?� Therefore,� the� soldering� must� be� conducted� with� great� care� so� as� to� prevent� malfunction� of� the� components� due� to� excessive� thermal�

�shock.�

�?� Preheating� :� Capacitors� shall� be� preheated� sufficiently,� and� the� temperature� difference� between� the� capacitors� and� solder� shall� be� within�

�100� to� 130℃.�

�?� Cooling� :� The� temperature� difference� between� the� capacitors� and� cleaning� process� shall� not� be� greater� than� 100℃.�

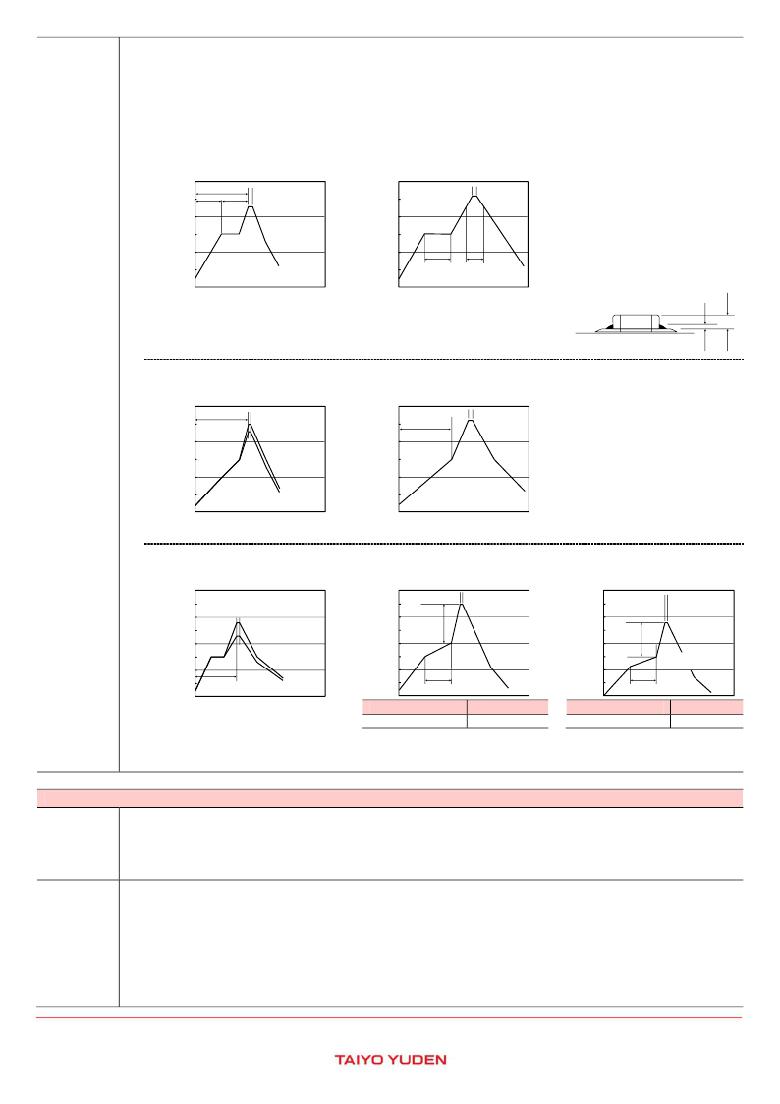

�[Reflow� soldering]�

�【Recommended� conditions� for� eutectic�

�soldering】�

�【Recommended� condition� for� Pb-free�

�soldering】�

�300�

�Preheating�

�60sec.� 60sec�

�230℃�

�Within� 10sec.�

�300�

�Peak�

�260℃� Max.�

�Within� 10sec.�

�200�

�Min.�

�Min.�

�Slow� cooling�

�200�

�Slow�

�cooling�

�100�

�100�

�Preheating150℃� Heating� above�

�60sec.� Min.�

�230℃�

�0�

�0�

�40sec.� Max.�

�Caution�

�①The� ideal� condition� is� to� have� solder� mass� (fillet� )controlled� to� 1/2� to� 1/3� of� the�

�thickness� of� a� capacitor.�

�②Because� excessive� dwell� times� can� adversely� affect� solderability,� soldering� duration� shall�

�be� kept� as� close� to� recommended� times� as� possible.�

�[Wave� soldering]�

�【Recommended� conditions� for� eutectic�

�【Recommended� condition� for� Pb-free�

�soldering】�

�soldering】�

�Solder�

�Capacitor�

�PC� board�

�1/2T~1/3T�

�T�

�300�

�200�

�Preheating�

�120sec.� Min.�

�230~250℃�

�Within� 3sec.�

�300�

�200�

�120sec.� Min.�

�Peak�

�260℃� Max.�

�Within� 10sec.�

�Slow� cooling�

�Preheating�

�Slow�

�cooling�

�100�

�0�

�100�

�0�

�150℃�

�Caution�

�①Wave� soldering� must� not� be� applied� to� capacitors� designated� as� for� reflow� soldering� only.�

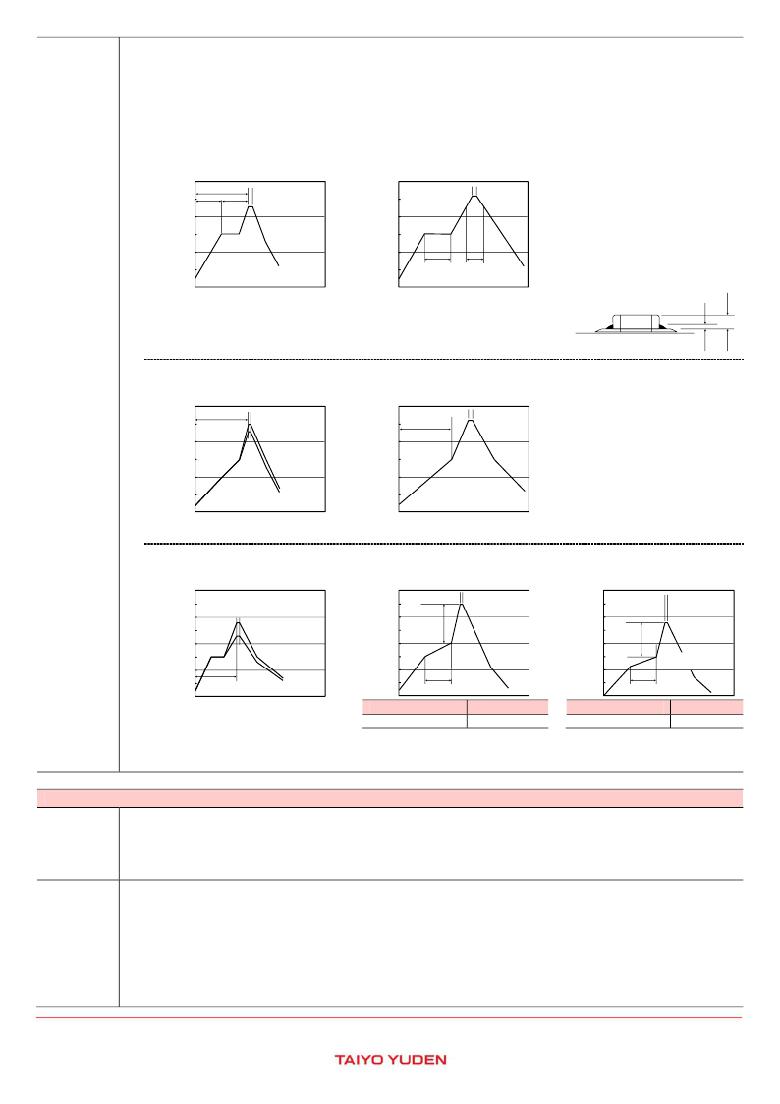

�[Hand� soldering]�

�【Recommended� conditions� for� eutectic�

�soldering】�

�【Recommended� condition� for� Pb-free�

�soldering】�

�400�

�300�

�230~280℃�

�Within� 3sec.�

�400�

�300�

�Peak�

�350℃� Max.�

�Within� 3sec.�

�400�

�300�

�Peak�

�280℃� Max.�

�Within� 3sec.�

�⊿T�

�200�

�200�

�Slow� cooling�

�200�

�⊿T�

�Slow� cooling�

�100�

�Slow� cooling�

�100�

�Preheating�

�150℃� Min.�

�100�

�Preheating�

�150℃� Min.�

�Preheating�

�0�

�60sec.� Min.�

�0�

�60sec.� Min.�

�0�

�60sec.� Min.�

�⊿T�

�⊿T�

�316type� or� less�

�⊿T≦150℃�

�325type� or� more�

�⊿T≦130℃�

�Caution�

�①Use� a� 50W� soldering� iron� with� a� maximum� tip� diameter� of� 1.0� mm.�

�②The� soldering� iron� shall� not� directly� touch� capacitors.�

�5.� Cleaning�

�◆Cleaning� conditions�

�1.� When� PCBs� are� cleaned� after� capacitors� mounting,� please� select� the� appropriate� cleaning� solution� in� accordance� with� the� intended� use�

�Precautions�

�Technical�

�considerations�

�of� the� cleaning.� (e.g.� to� remove� soldering� flux� or� other� materials� from� the� production� process.)�

�2.� Cleaning� condition� shall� be� determined� after� it� is� verified� by� using� actual� cleaning� machine� that� the� cleaning� process� does� not� affect�

�capacitor's� characteristics.�

�1.� The� use� of� inappropriate� cleaning� solutions� can� cause� foreign� substances� such� as� flux� residue� to� adhere� to� capacitors� or� deteriorate�

�their� outer� coating,� resulting� in� a� degradation� of� the� capacitor's� electrical� properties� (especially� insulation� resistance).�

�2.� Inappropriate� cleaning� conditions(� insufficient� or� excessive� cleaning)� may� adversely� affect� the� performance� of� the� capacitors.�

�In� the� case� of� ultrasonic� cleaning,� too� much� power� output� can� cause� excessive� vibration� of� PCBs� which� may� lead� to� the�

�cracking� of� capacitors� or� the� soldered� portion,� or� decrease� the� terminal� electrodes'� strength.� Therefore,� the� following� conditions� shall�

�be� carefully� checked;�

�Ultrasonic� output� :� 20� W/?� or� less�

�Ultrasonic� frequency� :� 40� kHz� or� less�

�Ultrasonic� washing� period� :� 5� min.� or� less�

�?� This� catalog� contains� the� typical� specification� only� due� to� the� limitation� of� space.� When� you� consider� the� purchase� of� our� products,� please� check� our� specification.�

�For� details� of� each� product� (characteristics� graph,� reliability� information,� precautions� for� use,� and� so� on),� see� our� Web� site� (http://www.ty-top.com/)� .�

�c_mlcc_prec_e-E02R01�

�发布紧急采购,3分钟左右您将得到回复。

相关PDF资料

KCM55QR71J106KH01K

CAP CER 10UF 63V 10% X7R 2220

KMF1.1123.1101

KMF POWER ENTRY MODULE W FILTER

KNA16300C16MA7TS

FILTER CAP ARRAY 16PF 35MA 25V

KNH21C104DA3T

FILTER CAP .10UF 2A 25V 0805

KRM55WR71E476MH01K

CAP CER 47UF 25V 20% X7R 2220

KS-3R3224-R

CAP SUPER 220MF 3.3V COIN SMD

KSR-2R8334-R

CAP SUPER 330MF 2.8V COIN SMD

L-14C9N0KV4T

CER INDUCTOR 9NH 0603

相关代理商/技术参数

JWL11BA

制造商:NKK 制造商全称:Nihon Kaiheiki Industry Co. Ltd. 功能描述:Internationally Approved TV Rated Rockers

JWL11BA1

制造商:NKK 制造商全称:Nihon Kaiheiki Industry Co. Ltd. 功能描述:Internationally Approved TV Rated Rockers

JWL11BA1A-A

功能描述:摇臂开关与扳钮开关 SPST TV8 RTD BLK CAP BODY/BARIR HORZ"O I"

RoHS:否 制造商:C&K Components 触点形式: 开关功能: 电流额定值:50 mA 电压额定值 AC: 电压额定值 DC:30 V 功率额定值: 端接类型: 执行器:Paddle 颜色: 安装风格:Panel 端子密封: 触点电镀: 照明:Not Illuminated 照明颜色:

JWL11BA2

制造商:NKK 制造商全称:Nihon Kaiheiki Industry Co. Ltd. 功能描述:Internationally Approved TV Rated Rockers

JWL11BA2A-A

功能描述:摇臂开关与扳钮开关 SPST TV8 RATED BLK BARIER/CAP VERT MARK

RoHS:否 制造商:C&K Components 触点形式: 开关功能: 电流额定值:50 mA 电压额定值 AC: 电压额定值 DC:30 V 功率额定值: 端接类型: 执行器:Paddle 颜色: 安装风格:Panel 端子密封: 触点电镀: 照明:Not Illuminated 照明颜色:

JWL11BA2A-H

功能描述:摇臂开关与扳钮开关 SPST TV8 RTD BLK CAP &BODY GRY BARIR VERT

RoHS:否 制造商:C&K Components 触点形式: 开关功能: 电流额定值:50 mA 电压额定值 AC: 电压额定值 DC:30 V 功率额定值: 端接类型: 执行器:Paddle 颜色: 安装风格:Panel 端子密封: 触点电镀: 照明:Not Illuminated 照明颜色:

JWL11BAA-A

功能描述:摇臂开关与扳钮开关 SPST TV8 RATED BLK BARRIER & CAP

RoHS:否 制造商:C&K Components 触点形式: 开关功能: 电流额定值:50 mA 电压额定值 AC: 电压额定值 DC:30 V 功率额定值: 端接类型: 执行器:Paddle 颜色: 安装风格:Panel 端子密封: 触点电镀: 照明:Not Illuminated 照明颜色:

JWL11BAA-H

功能描述:摇臂开关与扳钮开关 SPST TV8 RTD BLK CAP & BODY GRAY/BARRIER

RoHS:否 制造商:C&K Components 触点形式: 开关功能: 电流额定值:50 mA 电压额定值 AC: 电压额定值 DC:30 V 功率额定值: 端接类型: 执行器:Paddle 颜色: 安装风格:Panel 端子密封: 触点电镀: 照明:Not Illuminated 照明颜色: